New System Transforming the Composite Process

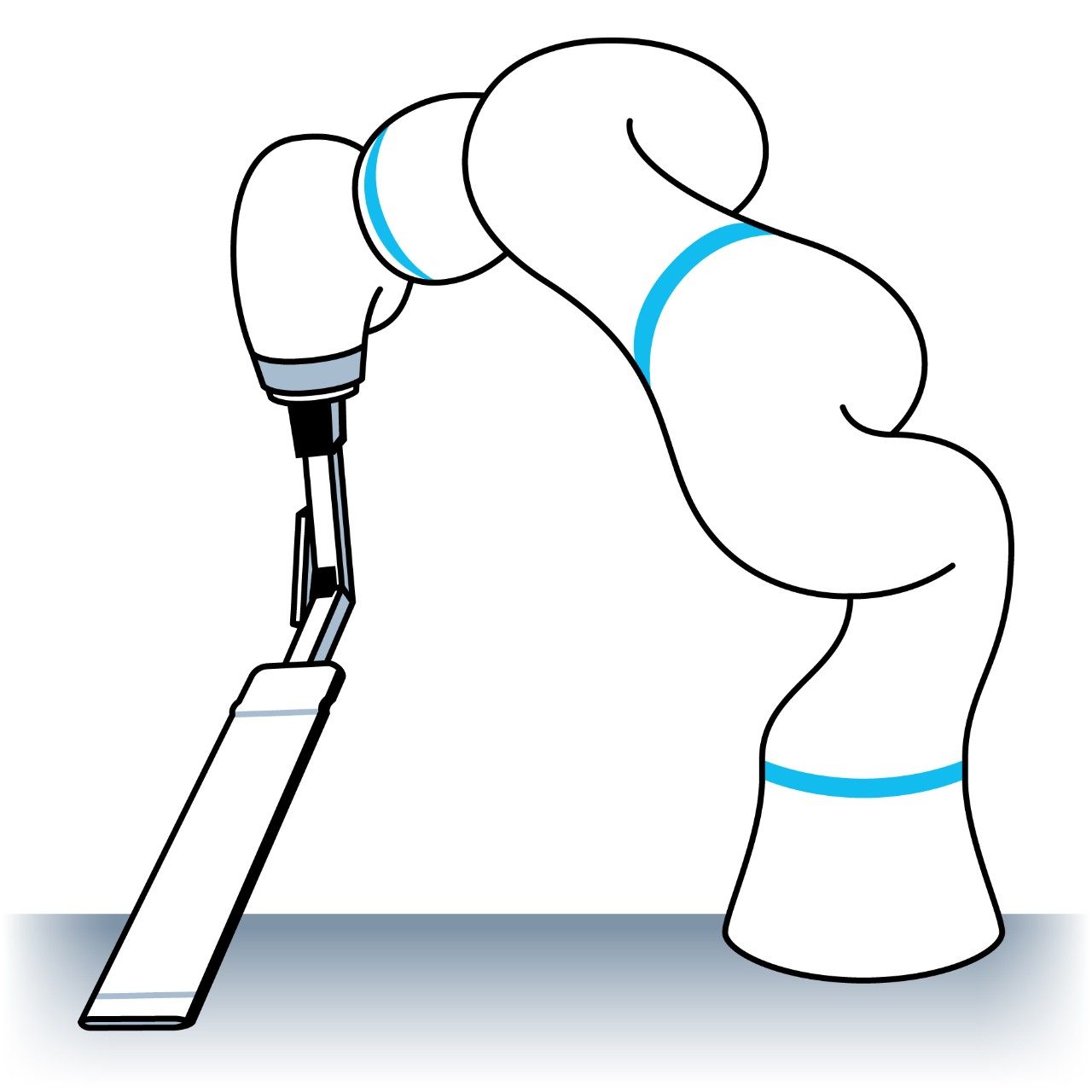

Think about robotic manufacturing. Are you imagining large, heavy machinery in a factory?

Consider a lighter touch…

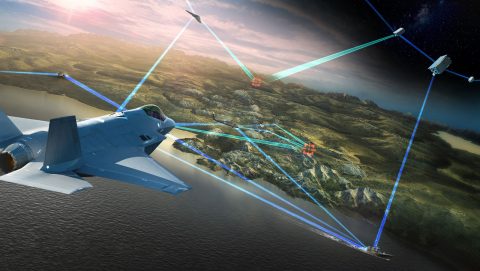

In partnership with the University of Southern California and Southwest Research Institute, our Advanced Technology Laboratories with funding by ARM (The Advanced Robotics for Manufacturing) Institute and Lockheed Martin Emerging Operations Technologies, developed a robotic cell to handle an intricate process previously thought to be unfeasible for robots to master.

What is it?

A four-robot system capable of adding delicate layer upon layer (about 240 in total) of composite material on a geometrically complicated laminate part. Composite material is two substances of different physical and chemical properties that when combined create a material that is lightweight and strong at the same time.

Why does it matter?

It saves time, money, improves quality, and reduces human fatigue.

The U.S. composite market is a $26.7 billion industry driven by time-insensitive and physically taxing labor. Developed in response to a project call issued by the ARM (Advanced Robotics for Manufacturing) Institute, this new process expands the scope of what robotic systems can perform in manufacturing.

How does it work?

Four robots work in unison. The first robot delivers a prepreg sheet into place. The second robot applies heat to make the material malleable. The third robot completes the material drape. Lastly, the fourth robot bolsters the sheet to ensure it remains in place.

Development of smart robotics assistants was a key to accomplishing this feat. By using artificial intelligence, robots can program themselves from the task descriptions and by utilizing vision-based sensing robots can monitor the process and prevent formation of defects and deliver consistent quality.

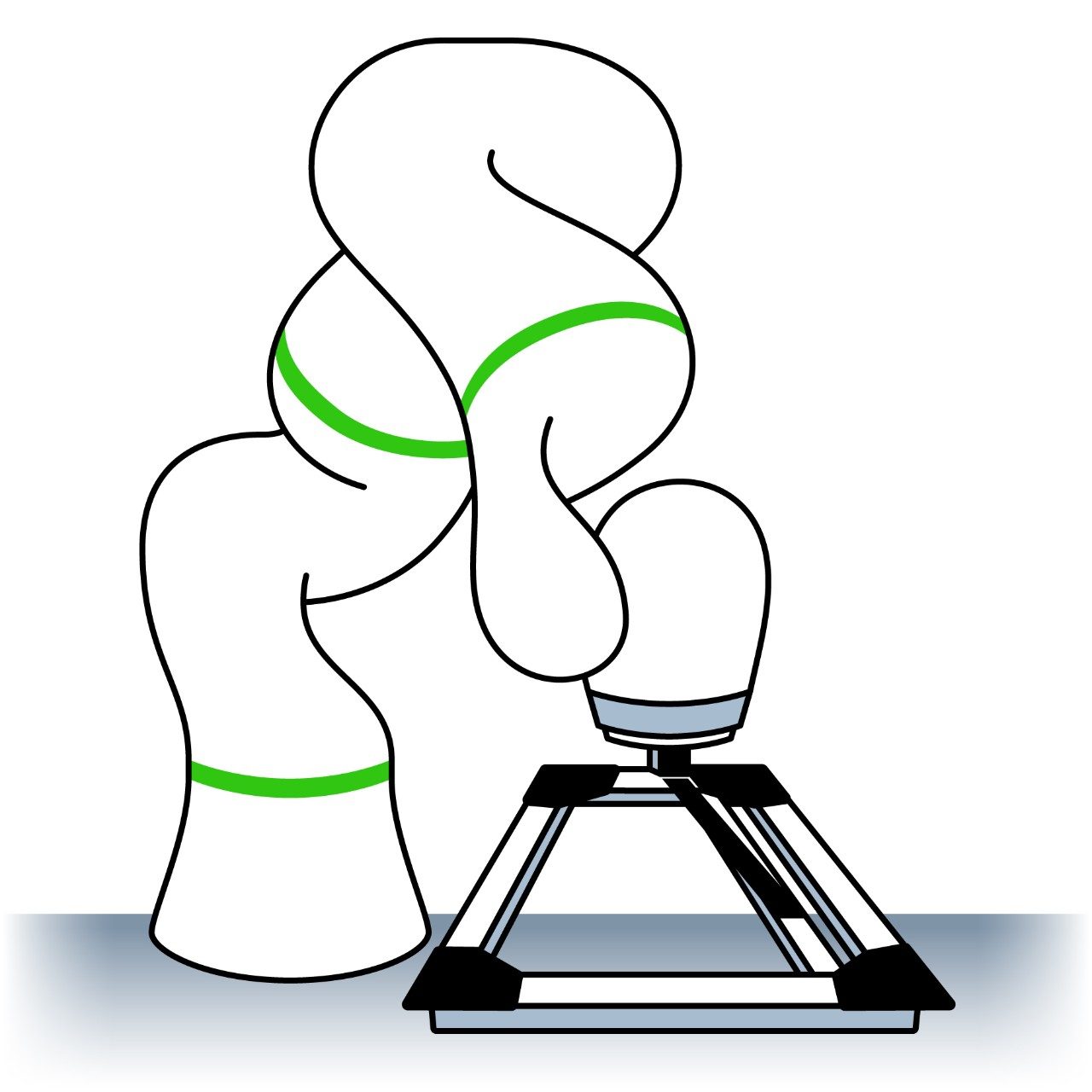

ROBOT ONE

Sheet Transport

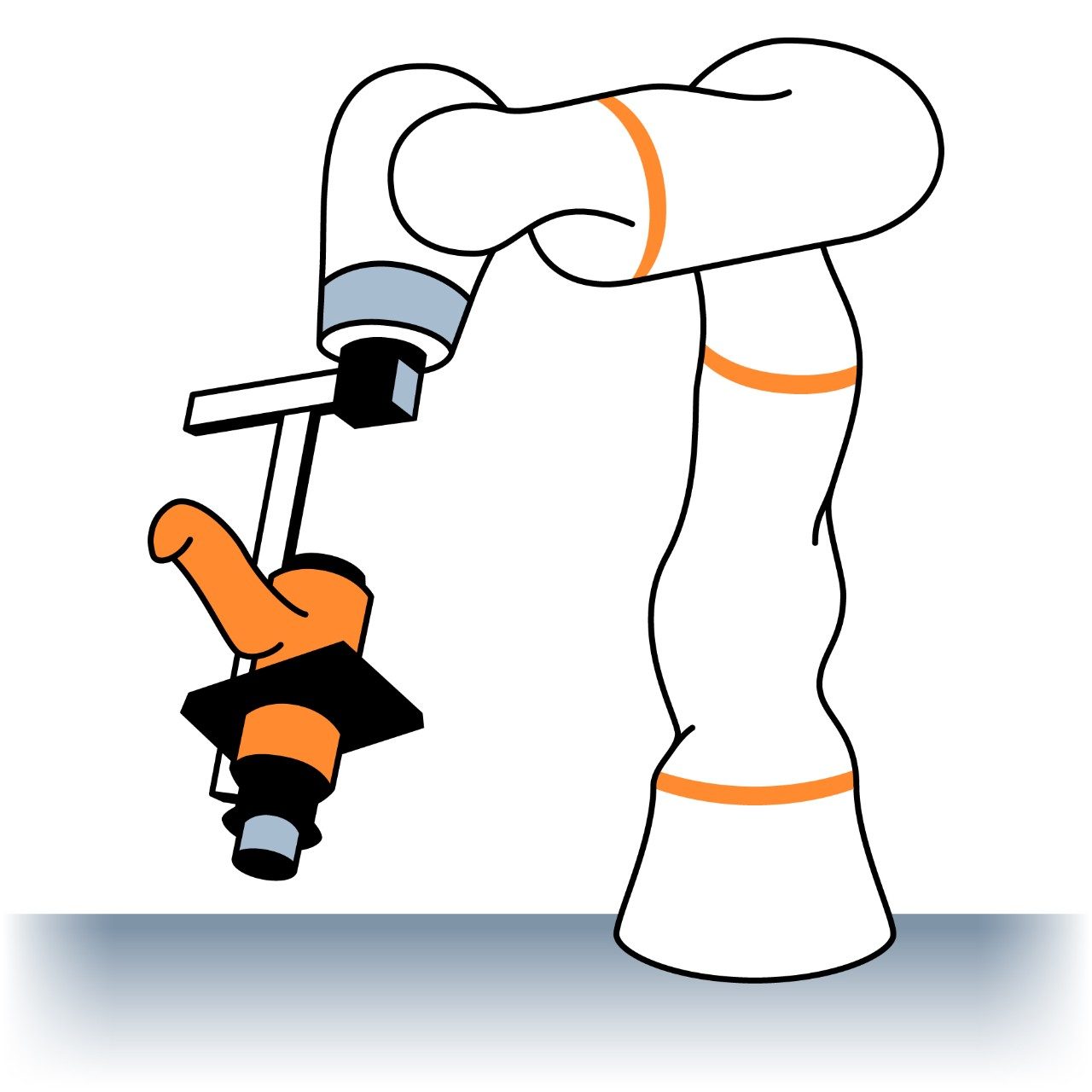

ROBOT TWO

Heating

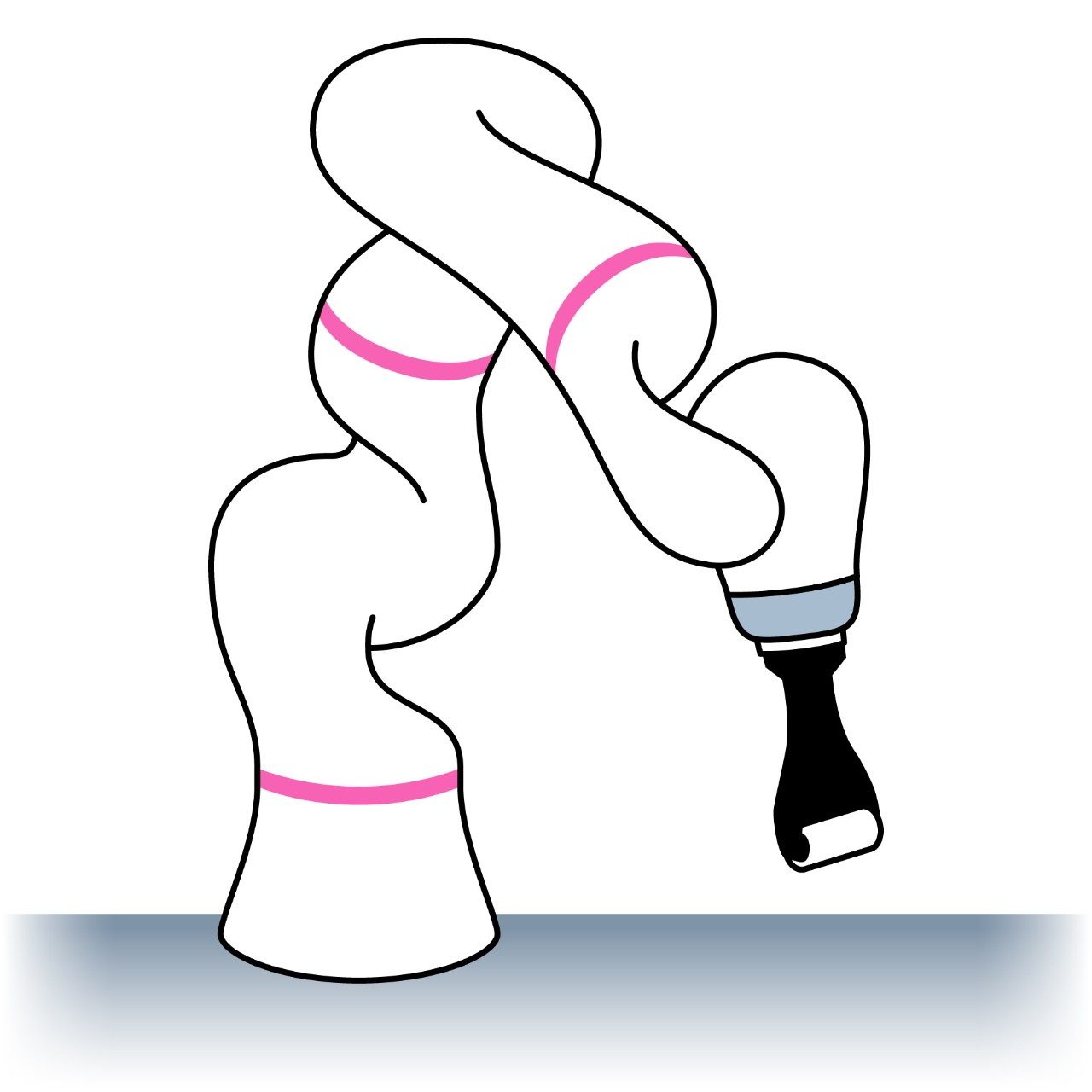

ROBOT THREE

Draping

ROBOT FOUR

Sheet Support

The best part?

It improves the human operator’s work experience, who still needs to observe and perform more complex tasks, like inspection. Not to mention, it saves technicians from repetitive strain and injury.

Here’s more background on how we’re digitally transforming with urgency across our business.

Through new innovations and partnerships, we are accelerating capabilities essential to our customers’ national security missions. This means we are embracing disruptive innovation in our processes, technology, and tools.

Additional Information:

We're engineering a better tomorrow.

Your individual skills play a critical role in changing the way the world works and helping us develop products that make it a safer place to achieve your goals. Our teams are made up of diverse employees from a wide range of disciplines and backgrounds, working together to tackle complex challenges and push the boundaries of innovation.

Explore our skill areas to find the right opportunity for you.